- Overview

- Product Description

- Detailed Photos

Basic Info.

Product Description

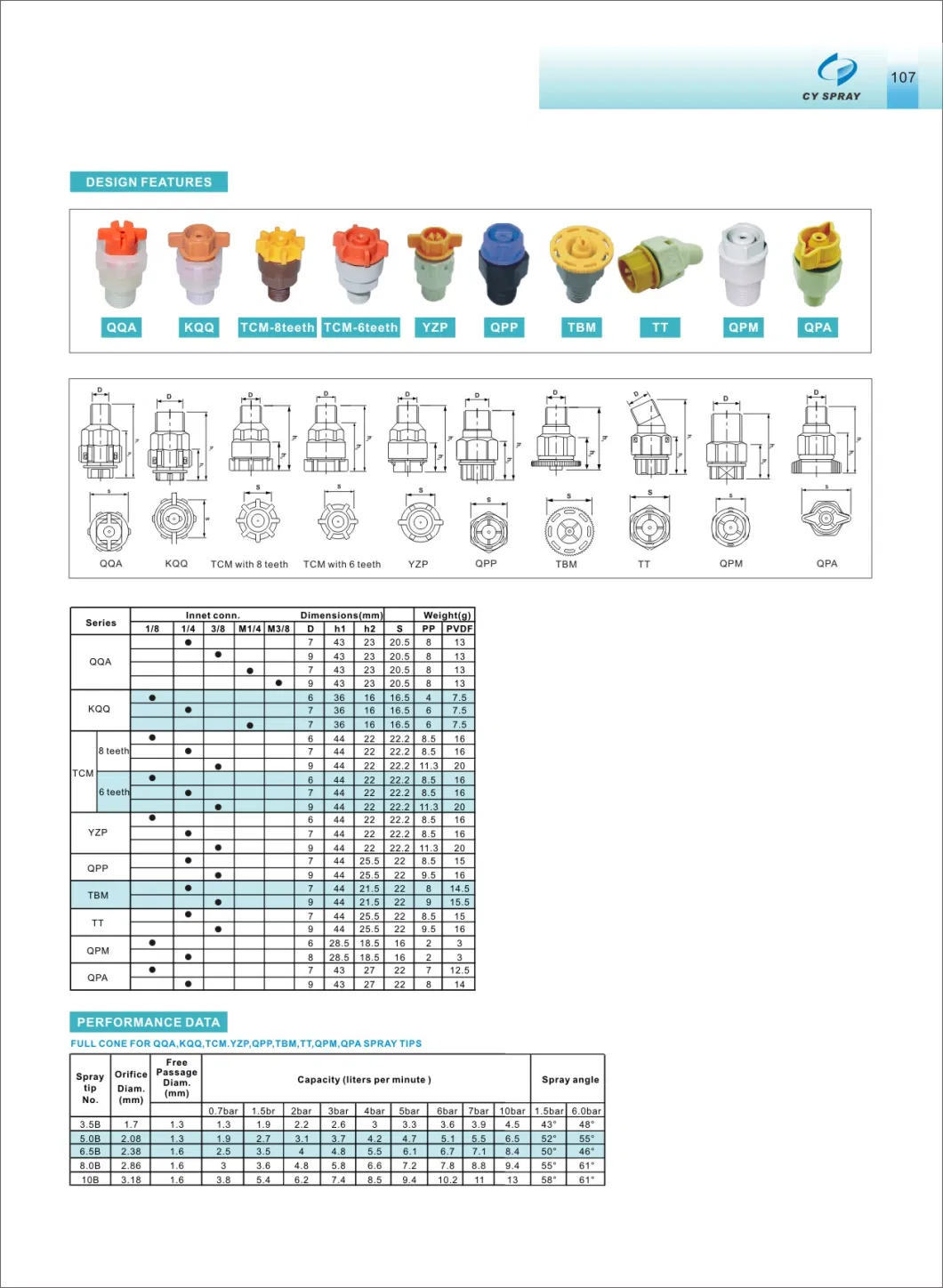

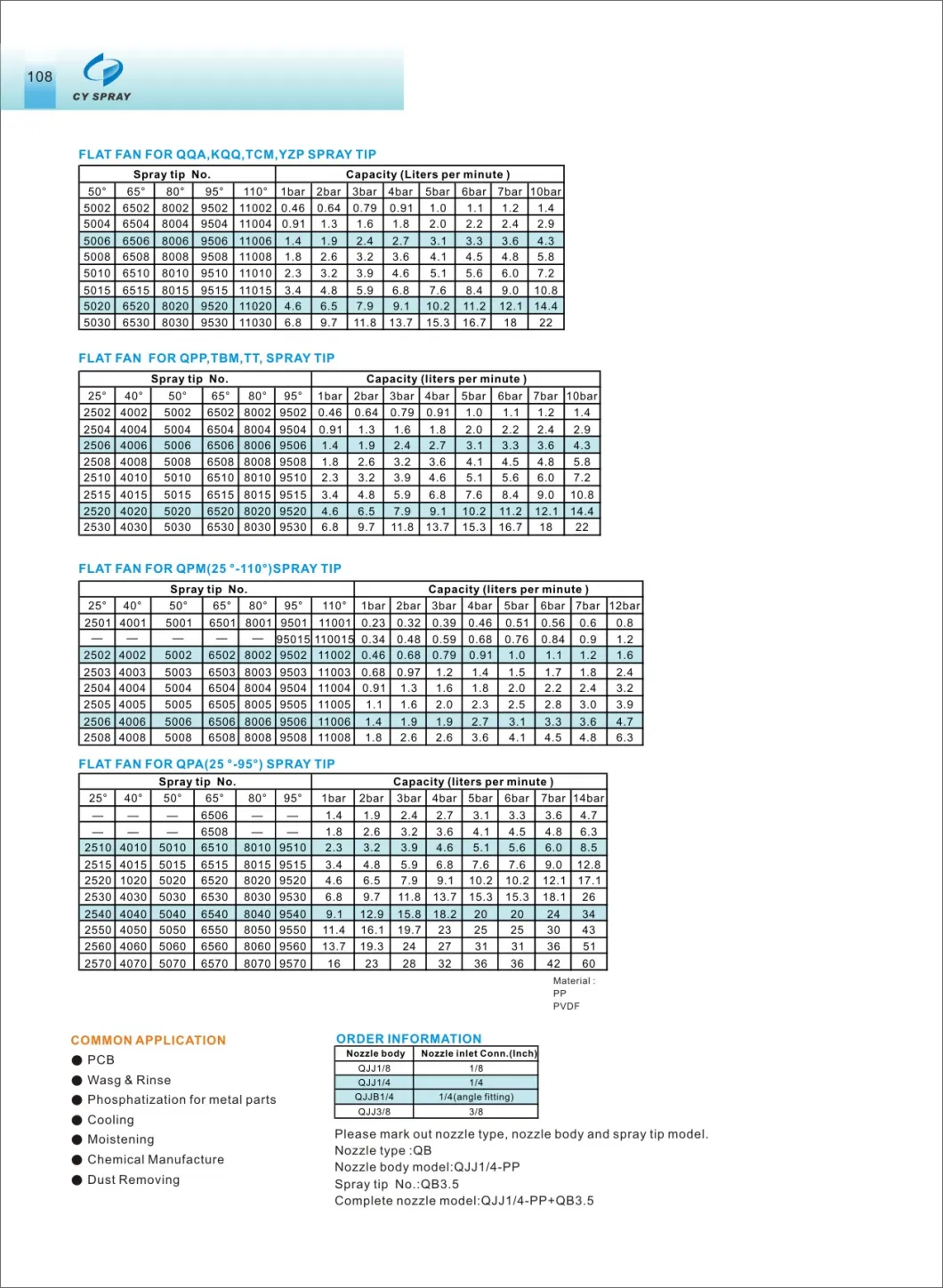

Easy split nozzle, made of glass fiber PP, carbon fiber pp and pvdf, featured high intensity, wearability and anticorrosion, suitable for washing and rinsing of corrosive solution, such as phosphate,acid solvent, max temperature for glass fiber pp is 82 degree, max temperature for carbon fiber is 120degree, while PVDF is high pure without pigment which can keep high purity in processing, and the max temperature is 148degree under 7KG pressure. Easy dismantling design, the nozzle and spray head can be quickly dismantled by rotating the spray head by 90 degrees to install it or split from the nozzle by hand. So it can significantly downtime during maintenance. Auto-orienting spray head, there is an interior block, which can keep the nozzle in the right position without manual adjustment.Anti-corrosion and wearable. Widely capacity choice Hollow Cone Spray Nozzles feature a standard hollow cone spray pattern with a round impact area. Uniform spray distribution is dropped in high flow rate and pressure with unobstructed flow passage and superior spray control design. Various spray angles are delivered in different pressure. The broad range of orifice diameter can be chose in the performance data table. Available size: 1/8", 1/4" and 3/8, abusolutely windtight between nozzle and spray head with an interior O-shaped NBR windtight circle,Easy split nozzle, specially appearance of spray head for grasp, Available spray head shapes, QC flat fan , QB full cone and QA hollow cone, and various capacities and angles are available.

| Material | PP,PVDF |

| Thread Type | BSPT |

| Thread Size | 1/8'', 1/4'',3/8" |

| Flow Rate | 0.12-18.1L/Min at 0.3-14BAR |

| Spray Angle | 50° -110° |

| Packing | Plastic Bag+ Carton, Special requirements are available |

| Custom Made | Available |

- PCB manufacturing

- Washing & Raining

- Dedusting

- Quenching & Cooling

- Gas Washing

- Deoxidation, Dearating and Aerating