Basic Info.

Model NO.

KX series micro whirly rotary spray head for clean

Operating Pressure

1.5-3 Bar

Spay Angle

360 Degree

Max. Tank Diameter

2 M

Connection

1/8", 1/4", 3/8"

Design Feature

Slide Bearing

Filtration

Line Strainer with a Mesh Size of 0.3mm / 50 Mesh

Common Application

Cleaning and Rinsing of Tanks / Containers

Transport Package

Carton

Specification

10*10*10

Origin

Cn

HS Code

8422909000

Production Capacity

10000 PCS Per Month

Product Description

Micro whirly clean in place tank washing nozzle

Design features :

1. Small diameter to insert in small openings

2. Excellent cleaning power

3. Stainless steel AISI 316 SS

4. Slide bearing

5. Very compact design, self rotating

6. Driven and lubricated by the cleaning fluid

Common application:

Soup kettles

Yeast propagation tanks

Batch processing vessels

Fluid bed dryers

Ink and paint mixing vats

Brew kettles

Storage tanks

Spray dryers

Commercial ovens

e.g: in food industry, beverage industry, pharmaceutical industry and chemical industry

Benefits:

Provides a high energy impinging spray for deep cleaning.

Reduces water consumption.

Reduces chemical consumption.

Increases vessel availability.

Reduces confined space entry.

Provides consistent cleaning.

Helps fight against bacterial infections and other "off taste" producing elements

Product Photo:

Product photo of tank cleaning nozzle:

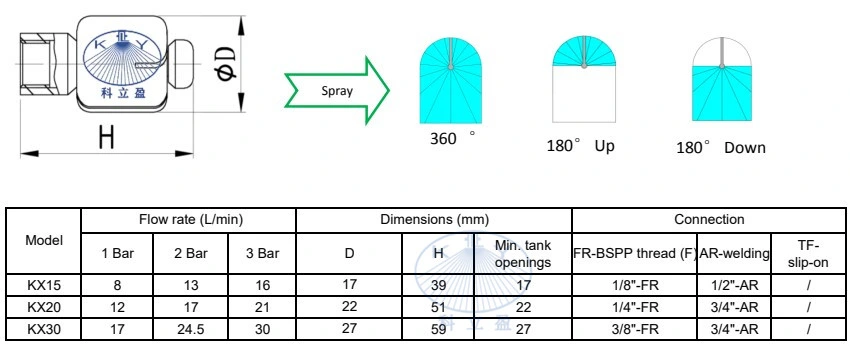

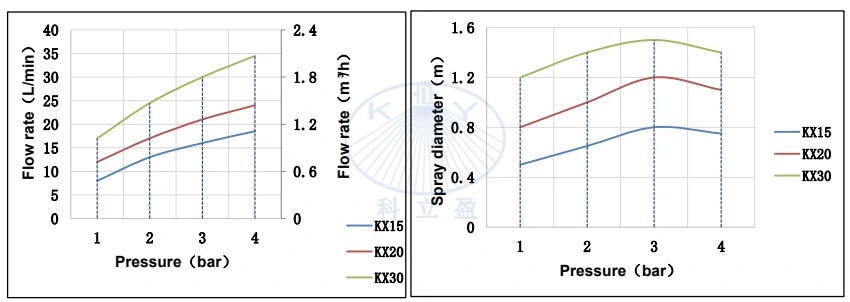

Performance data of rotary spray nozzle:

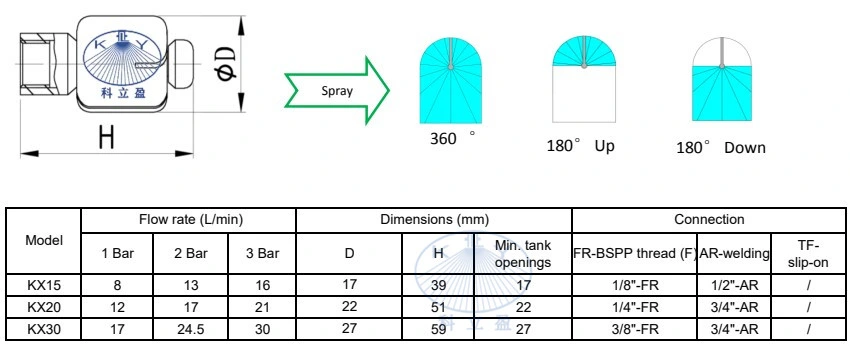

Dimension of tank cleaning nozzle:

| Model: | KX tank washing nozzle |

| Material: | 316 ss |

| Connection: | 1/8''BSPP, 1/4" BSPP, 3/8"BSPP |

| Bearing: | slide bearing |

| Pressure: | 1.5-3 bar |

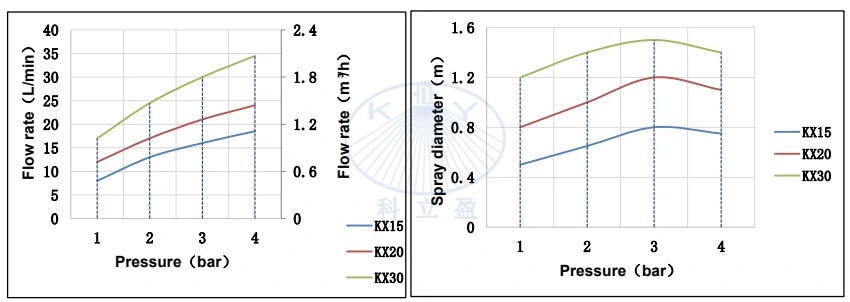

| Spray diameter: | 0.8-1.5m |

| Temperature: | 95° |

| Installation: | Operation in every direction is possible |

| Filtration: | Line strainer with a mesh size of 50 Mesh |

| Application: | rinsing and cleaning of tank or equipment |

Design features :

1. Small diameter to insert in small openings

2. Excellent cleaning power

3. Stainless steel AISI 316 SS

4. Slide bearing

5. Very compact design, self rotating

6. Driven and lubricated by the cleaning fluid

Common application:

Soup kettles

Yeast propagation tanks

Batch processing vessels

Fluid bed dryers

Ink and paint mixing vats

Brew kettles

Storage tanks

Spray dryers

Commercial ovens

e.g: in food industry, beverage industry, pharmaceutical industry and chemical industry

Benefits:

Provides a high energy impinging spray for deep cleaning.

Reduces water consumption.

Reduces chemical consumption.

Increases vessel availability.

Reduces confined space entry.

Provides consistent cleaning.

Helps fight against bacterial infections and other "off taste" producing elements

Product Photo:

Product photo of tank cleaning nozzle:

Performance data of rotary spray nozzle:

Dimension of tank cleaning nozzle: